Grow capabilities with the leaders in Cultivation Facility Design

Upgrade your growth capabilities for a greener, smarter, and more inviting world.

Controlled environment

We understand that the environment and atmosphere of a room play a big role in shaping the customer experience.

You’ll have complete control over the lighting levels, temperatures, and even aromas that will contribute to creating a special and memorable retail environment.

Horticulture for a sustainable future

We are dedicated to helping horticulture to achieve your goals. Our MEP solutions are the systems that make buildings come to life, and we understand the importance of creating an environment that brings life to indoor spaces for a sustainable future.

Innovation in agriculture

Our innovations include keeping our cultivation facility at the perfect temperature and humidity. We know that indoor cultivation for delicate plants requires a specific environment to thrive. Our HVAC solutions are designed with that in mind.

Our customers are saying

Don’t take our word for it, see what our customers are saying.

Latest cannabis articles

We Innovating by enhancing the avenues of collaboration and communication

Hydronic HVAC Systems: A Sustainable Solution for Chicago’s Harsh Winters

Discover how hydronic HVAC systems improve energy efficiency and comfort in Chicago’s harsh winters. Learn how Mintropy’s high-rise designs, like.

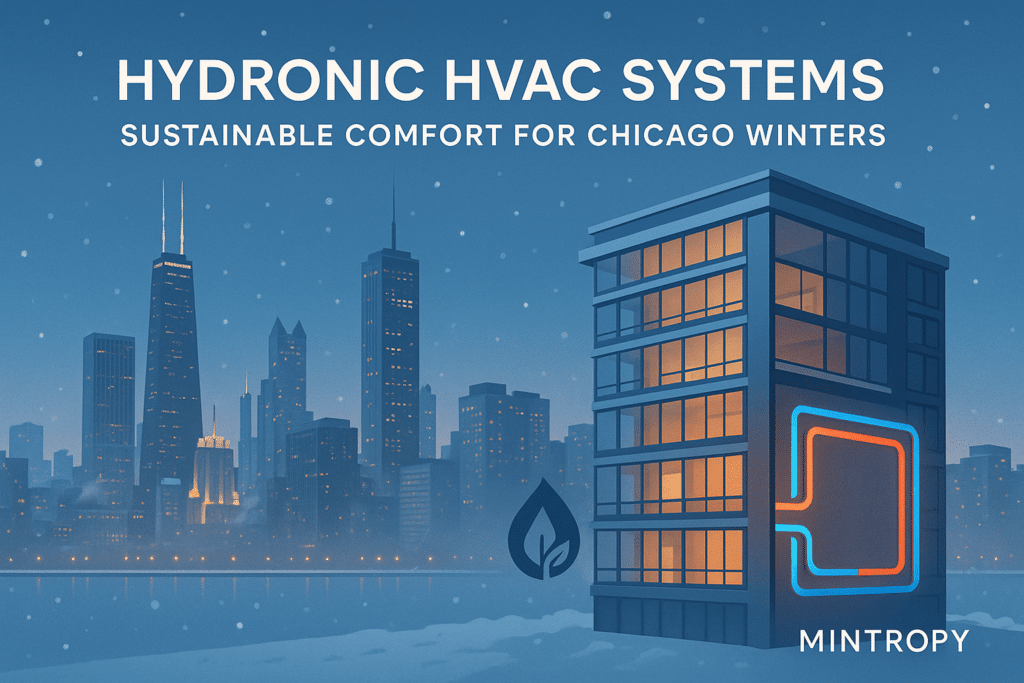

Cloud-Based Building Management Systems: From High-Rises in Chicago to Campuses in Phoenix

Discover how cloud-based Building Management Systems are transforming energy efficiency in high-rises and campuses. Contact Mintropy to future-proof your building..

MEP Design Trends in Tucson: Innovations Shaped by Climate and Code

Explore cutting-edge MEP design trends in Tucson that meet modern developer needs—code-compliant, energy-efficient systems designed to thrive in the desert.

Hydronic HVAC Systems: A Sustainable Solution for Chicago’s Harsh Winters

Discover how hydronic HVAC systems improve energy efficiency and comfort in Chicago’s harsh winters. Learn how Mintropy’s high-rise designs, like.

Cloud-Based Building Management Systems: From High-Rises in Chicago to Campuses in Phoenix

Discover how cloud-based Building Management Systems are transforming energy efficiency in high-rises and campuses. Contact Mintropy to future-proof your building..

MEP Design Trends in Tucson: Innovations Shaped by Climate and Code

Explore cutting-edge MEP design trends in Tucson that meet modern developer needs—code-compliant, energy-efficient systems designed to thrive in the desert.