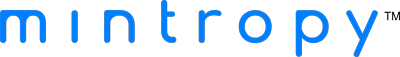

The Machine Shop, Chicago, IL

Introduction

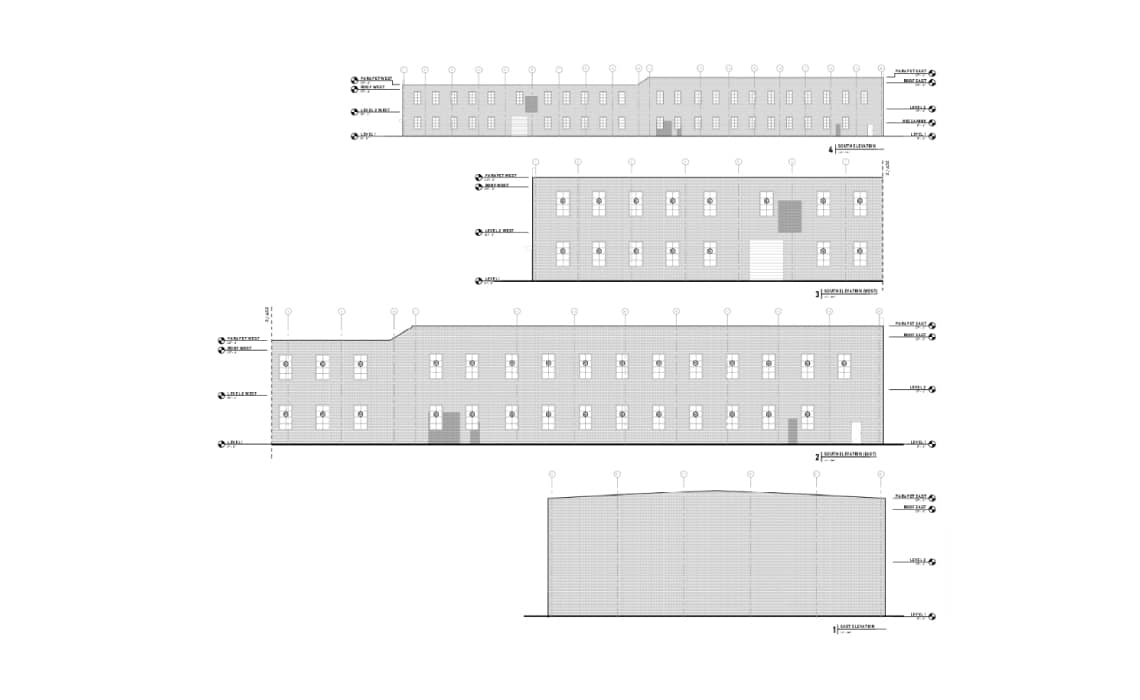

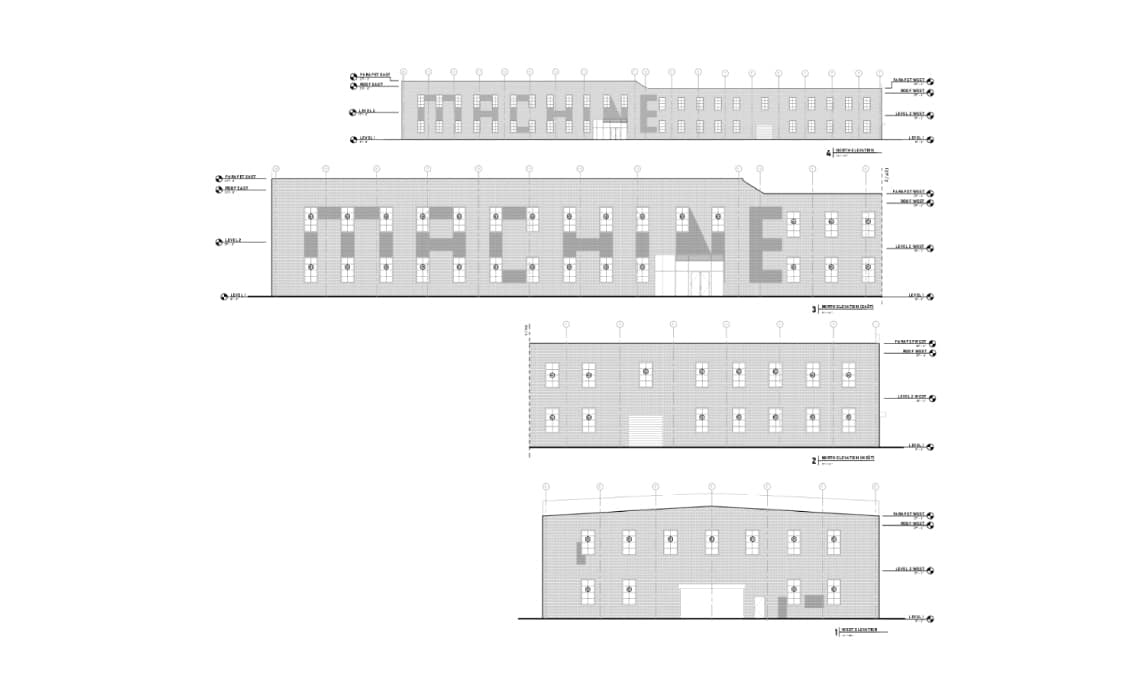

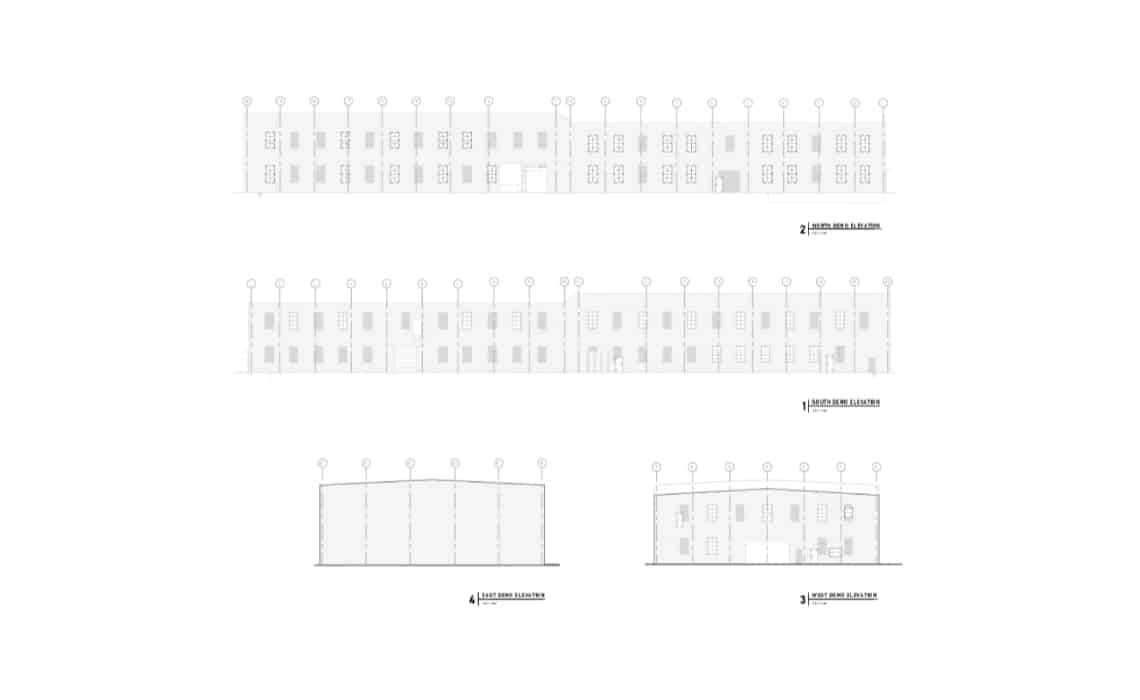

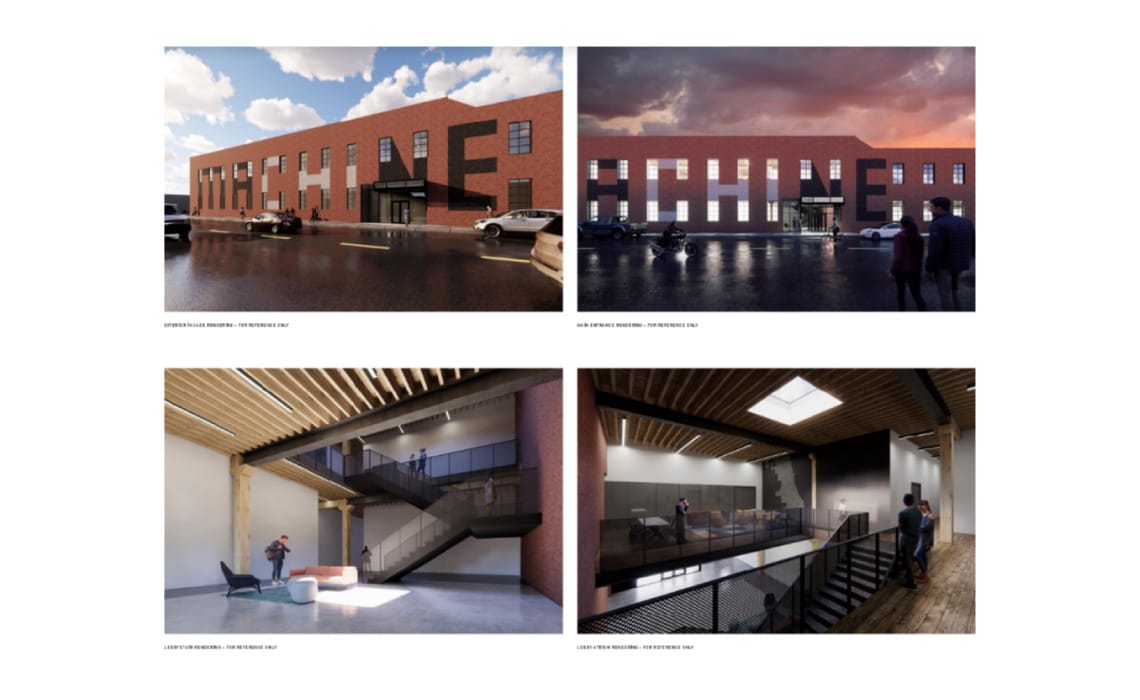

The Machine Shop renovation project was a challenging, yet successful undertaking for Mintropy MEP Company. The project involved converting an existing 60,000 Sq. Ft. industrial warehouse facility into new office and industrial tenant spaces. The scope of the project included the addition of new amenities such as restrooms, a lobby, lounge, and future bar areas. The team was able to successfully transform the warehouse into functional and desirable spaces for tenants while maintaining the building’s industrial aesthetic. The project was completed on time and within budget, and the finished product met the expectations of both the tenants and the owner. Overall, the Machine Shop renovation project serves as an excellent example of how Mintropy MEP Company’s expertise in building systems can help revitalize an industrial space and make it suitable for modern use.

Mechanical

The mechanical scope of the project involved the installation of new roof top unit type (single zone, local controls) systems and new ductwork distribution from these units. The project also included the installation of new toilet exhaust and distribution systems, new general exhaust and distribution systems, and local controls. The mechanical scope also included the design and installation of a new gas distribution system for the building.

Electrical

The electrical scope of the project involved the design of the power distribution for the building, as well as the circuiting for new building-mounted exterior lighting, electrical power outlets, and fire alarm speakers/strobe. The project also included the design of the fire alarm detection and alarm system device layout.

Plumbing

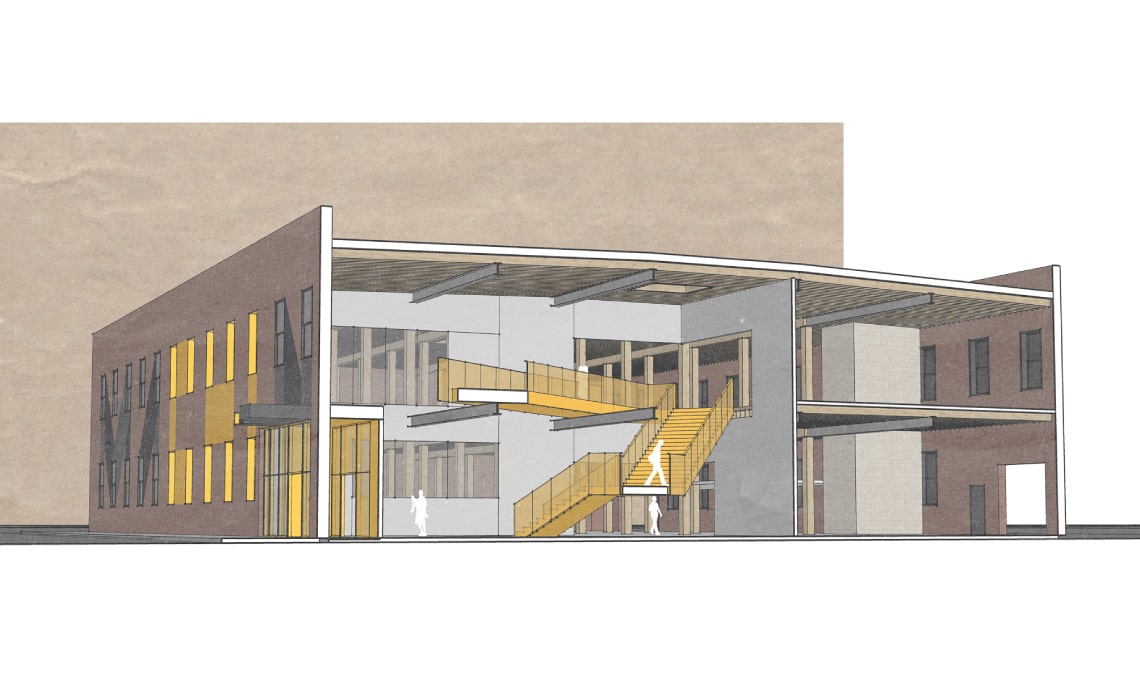

The plumbing scope of the project involved the design and installation of a complete sanitary drainage and vent system, complete domestic water (cold and hot) system, riser diagrams, recirculation system, and the specification of plumbing fixtures. The plumbing scope also included the design of the main distribution systems for the renovated facility and detailed design for common areas such as toilets, corridors, and lobby areas.

Key Features

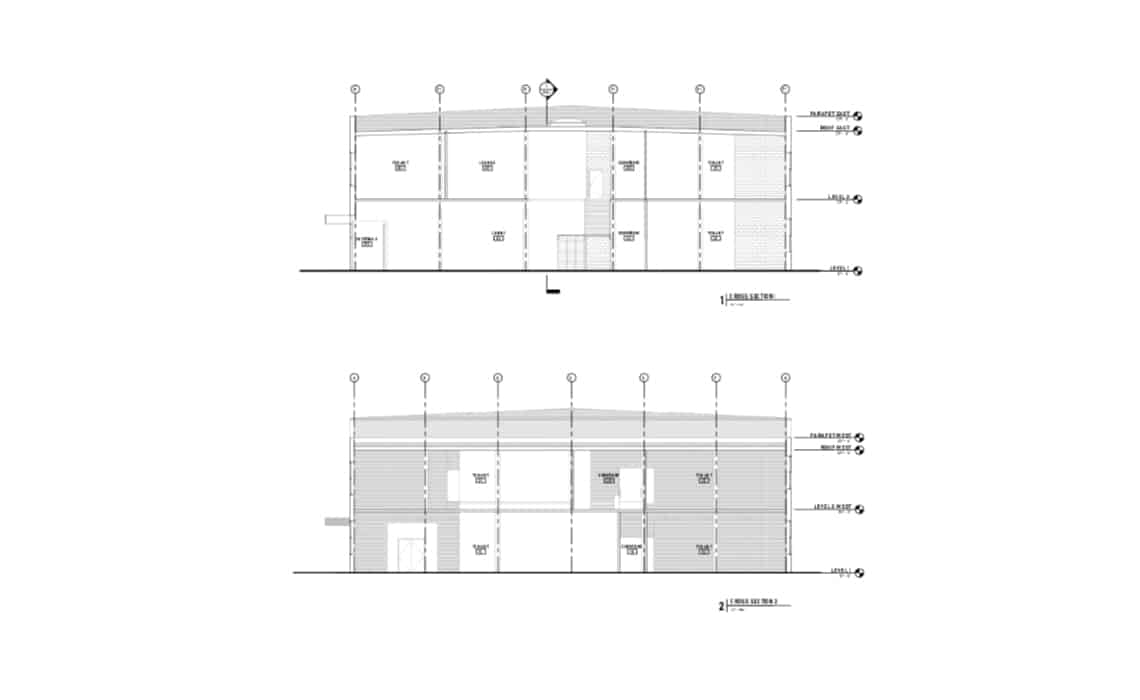

- Provide mechanical, electrical, and plumbing engineering services for permit and construction engineering documents for the Core and Shell of the renovated facility

- Main Distribution Systems design for the renovated facility

- Distribution mains for Mechanical, electrical, and plumbing to each of the tenant spaces

- Detailed design for common areas such as toilets, corridors, and lobby areas

- Building located in a market area with a total area of 60,000 Sq. Ft.

- Improving the functionality and efficiency of the building by updating its mechanical, electrical, and plumbing systems.

Roles

- Removal and replacement of existing mechanical systems such as the old roof top unit, ductwork, and controls.

- Design and installation of new mechanical systems such as new roof top units, ductwork distribution, toilet exhaust and distribution, general exhaust and distribution, and local controls.

- Design and installation of new gas distribution system

- Design of power distribution and lighting systems, and electrical power outlets

- Design and installation of fire alarm detection and alarm system

- Design and installation of complete sanitary drainage and vent system, complete domestic water (cold and hot) system, riser diagrams, recirculation system, and plumbing fixtures

- Design and installation of main distribution systems for the renovated facility and detailed design for common areas such as toilets, corridors, and lobby areas

- Overall Improving the functionality and efficiency of the building by updating its mechanical, electrical, and plumbing systems.

Summary

The Machine Shop renovation project was undertaken by Mintropy MEP Company to enhance the functionality and efficiency of the 60,000 Sq. Ft. building located in a market area. The project involved upgrading the mechanical, electrical, and plumbing systems of the building. The mechanical scope of the project included the removal and replacement of the old rooftop unit and ductwork, as well as the installation of new systems such as new rooftop units, ductwork distribution, toilet exhaust and distribution, general exhaust and distribution, and local controls. The electrical scope focused on power distribution, lighting systems, and electrical power outlets. The plumbing scope included the design and installation of a complete sanitary drainage and vent system, a complete domestic water (cold and hot) system, riser diagrams, a recirculation system, and plumbing fixtures. The project also included the design and installation of main distribution systems for the renovated facility, as well as detailed designs for common areas such as toilets, corridors, and lobby areas. Overall, the project aimed to enhance the overall functionality and efficiency of the building by updating its mechanical, electrical, and plumbing systems.

Others project

Center for Green Technology – Chicago, IL

The Center for Green Technology renovation project was a challenging but successful undertaking for Mintropy

Introduction This project involved an existing 28-story high-rise building with a complex plant system. The

This massive, 310,000 square-foot, multi-story residential building with an underground parking area is one of

Introduction Mintropy, LLC was engaged to provide mechanical and plumbing engineering services for the renovation…

Center for Green Technology – Chicago, IL

The Center for Green Technology renovation project was a challenging but successful undertaking for Mintropy

Introduction This project involved an existing 28-story high-rise building with a complex plant system. The

This massive, 310,000 square-foot, multi-story residential building with an underground parking area is one of

Introduction Mintropy, LLC was engaged to provide mechanical and plumbing engineering services for the renovation…